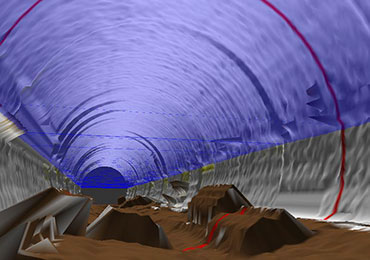

Using high-resolution sonar units (which may be skid, float, or robotic tractor mounted) we can survey and fully assess pipelines 10″ to 120″ in diameter. We can measure debris and sediment depth in pipelines and shafts.

As the sonar scanner is moved through the pipeline, an indication of distance traveled is shown and recorded on the screen. Internal sensors monitor the attitude of the scanning device as pitch and roll indicators in analogue and digital form on the screen show the orientation of the unit.

Features & benefits

- Combines with CCTV to provide simultaneous image of pipe both above and below waterline.

- Provides “real-time” cross-sectional views of the pipe, utilizing high resolution/short range sonar.

- Provides and quantifies accurate dimensional data on silt level, grease accumulation, pipe deformation, offsets, blockages, etc. below the water line in partially charged lines.

- Sonar inspection provides a two-dimensional profile of the interior pipe wall.

Sonar profiling has proven useful in a variety of applications. Surcharged pipelines, siphons, river crossings, and force mains can be inspected with confidence and without the costly disruption associated with bypass pumping. Data can be delivered in both hard copy and digital format.